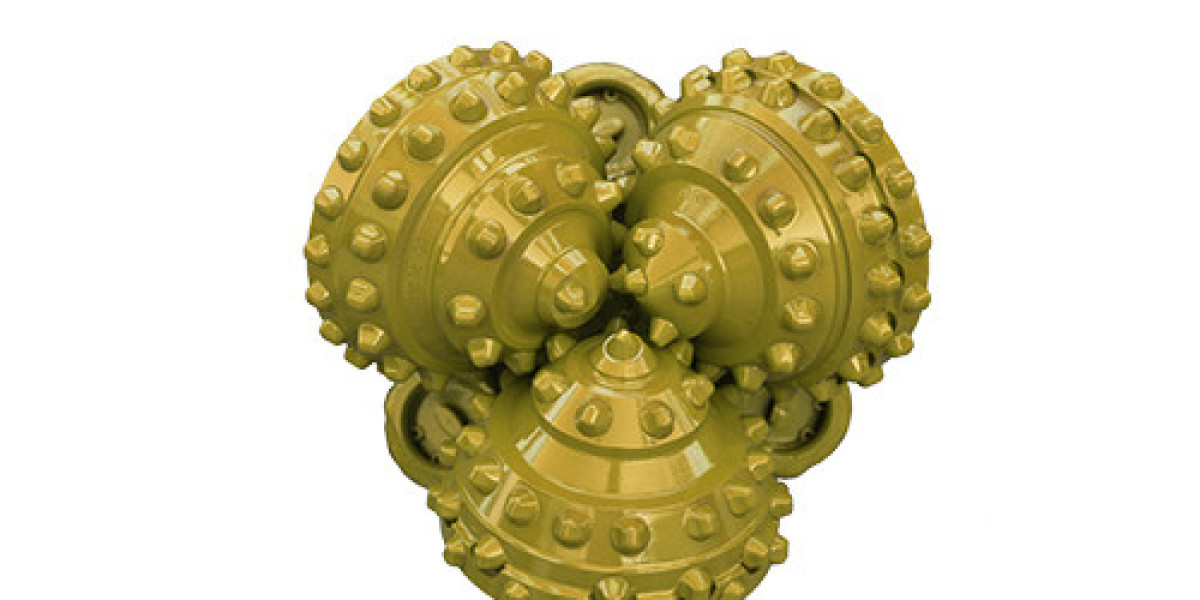

Breaking in a new tricone bit is crucial to ensure it runs well and durable. You’ll protect its working more effectively and you shouldn’t have as long of a time period that it’s not working properly. We’ll cover why you should break in a new tricone bit, what you need to know to do it properly, some advice on how to make purchases last, some things to avoid, and how doing it correctly can help with your drilling.

Tricone Bit Breaking Key Points:

Once you have a new tricone bit, it is important to break it in before you go to work. This helps to eliminate any remaining material from the bit being made. Training the bit the right way can help it work well and last longer.

Tasks to do While Breaking In the Tricone Bit 1.

The first is to inspect the tricone bit for damage. And just double-check: everything OK before you get going?

Screw the bit tricone to the drill and insert into the hole. First allow the bit to work through for a few minutes as you turn it around quietly.

Gradually, make that the pace a bit faster and add some more weight to the bit as it continues to drill. Keep your eye on it to ensure it’s functioning properly.

Do a little bit of drilling, pull it out, look at the tricone bit and see how it’s wearing. Repeat the break-in steps if you need to, just to be sure it works like it should.

Tricone Bit Working And Extend Lifespan:

Use the appropriate drilling fluid for the type of soil you are drilling to prevent unnecessary bit wear.

Maintain correct drilling settings — speed, as well as weight on the bit — to prevent overheating.

Inspect the tricone bit for wear or damage often, and change out as necessary to avoid losing time.

Some common mistakes to avoid when breaking in new tricone bit.

If it is used too fast, or with too much weight on the bit during break-in, too much wear can result.

If you forget to check your bit for damage before using it, you may cause damage -to the bit and to your horse!

Failure to break in the tricone bit as per the manufacturer’s manual may lead to underperformance, as well as a reduced useable life.

Benefits of following break-in processes for efficient drilling:

By properly breaking in a new tricone bit, you can extend its effective life span and help it to perform more effectively. This can mean better drilled holes and less downtime for you, saving you time and money. Follow the suggestions to ensure your tricone bit work fine from the beginning. And, you know caring for your tricone bit is a necessary step towards successful drilling.

All in all, breaking in a new tricone bit is an important part of the process that should not be overlooked. When you follow the right steps and avoid common mistakes, you can help that bit do its job better, last longer and perform more efficiently in getting the job done. And last, but not least, please follow the manufacturer’s instructions and always inspect and maintain your tci tricone bit. When good care is taken, your DeepFast tricone bit will be drilling for long time.