Polyester yarn, a synthetic fiber derived from petroleum-based products, has become a cornerstone of China’s textile industry. Known for its durability, affordability, and versatility, polyester yarn in China is woven into countless products—from everyday clothing to industrial fabrics. China, as the world’s largest producer and exporter of polyester yarn, plays a pivotal role in shaping global supply chains and manufacturing trends.

The Manufacturing Process

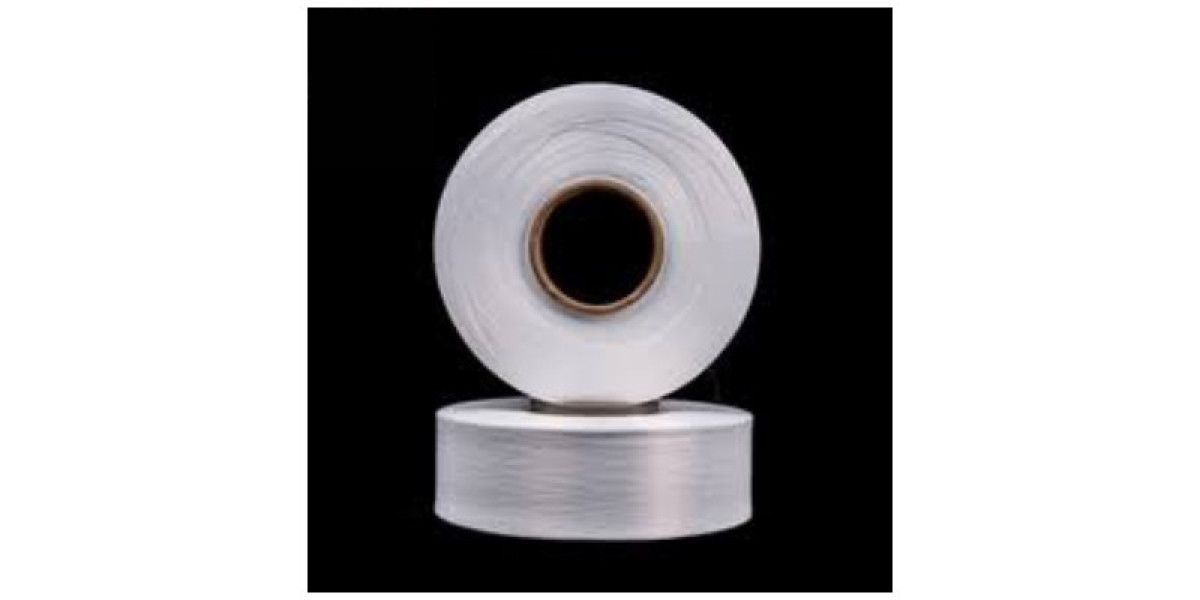

Polyester yarn production begins with purified terephthalic acid (PTA) and monoethylene glycol (MEG). Through polymerization, these raw materials form polyethylene terephthalate (PET) chips, which are then melted and extruded into fine filaments. These filaments are spun into yarn through processes like texturizing or twisting. Chinese manufacturers have optimized this workflow with advanced machinery, ensuring high output and consistent quality.

China’s Industry Landscape

The country accounts for over 65% of global polyester yarn production, with major hubs in Zhejiang, Jiangsu, and Fujian provinces. Key players include Tongkun Group and Zhejiang Hengyi Group, which leverage economies of scale to maintain competitive pricing. Government support for infrastructure and R&D has further cemented China’s dominance. Additionally, the rise of vertical integration—where companies control everything from raw materials to finished products—enhances efficiency and reduces costs.

Diverse Applications

l Polyester yarn’s adaptability makes it indispensable across sectors:

l Apparel: Blended with cotton or wool for wrinkle-resistant, easy-care garments.

l Home Textiles: Used in bedding, curtains, and upholstery due to its color retention and strength.

l Industrial Uses: Found in tire cords, conveyor belts, and safety gear. China’s ability to customize yarn properties (e.g., flame resistance, moisture-wicking) caters to niche markets, driving export growth.

Sustainability Challenges and Innovations

While polyester’s low cost fuels demand, environmental concerns linger. Petroleum dependency and microplastic pollution have spurred initiatives like closed-loop recycling systems. Chinese firms are investing in biodegradable alternatives and chemical recycling technologies. For instance, some factories now transform post-consumer plastic bottles into recycled polyester (rPET) yarn—a trend aligning with global circular economy goals.

Future Outlook

The polyester yarn market in China is poised for steady growth, driven by e-commerce demand and technical textiles for sectors like healthcare and automotive. However, balancing scalability with eco-friendly practices remains critical. Companies adopting green certifications or digital traceability tools will likely gain a competitive edge.

For businesses seeking reliable polyester yarn suppliers or detailed industry insights, xingfatex.com offers comprehensive resources, from product catalogs to market analyses. Explore their platform to connect with top-tier manufacturers and stay ahead in this dynamic sector.