Introduction

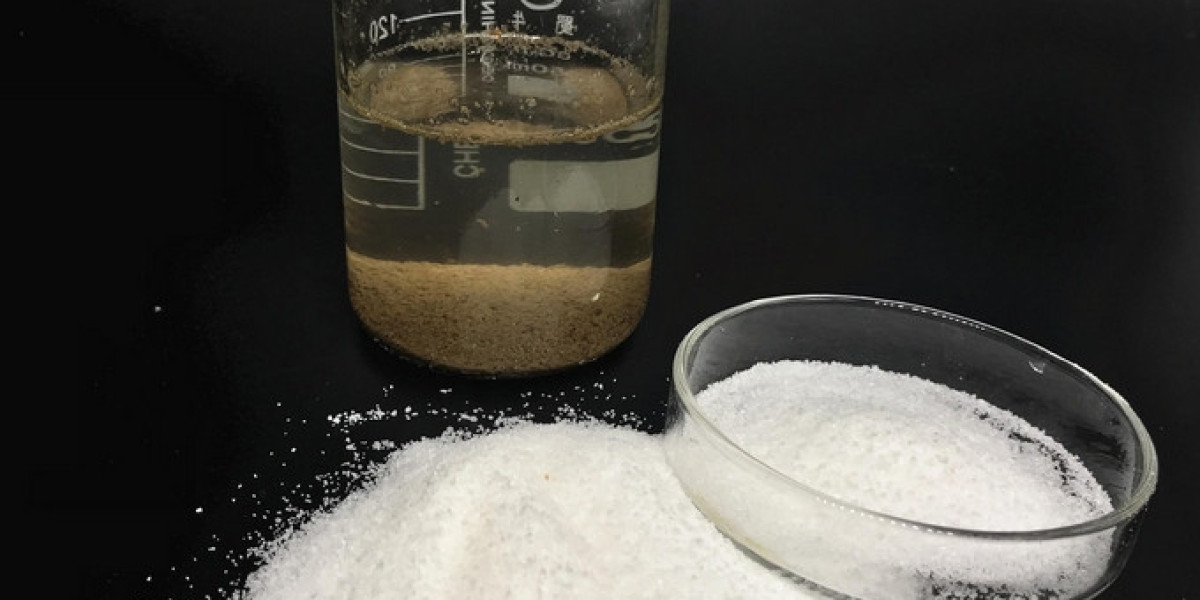

Water treatment Polyacrylamide Chemicals have become indispensable in modern industrial and municipal wastewater management. As a high-efficiency flocculant, polyacrylamide (PAM) excels in coagulating suspended solids, reducing sludge volume, and optimizing water clarity. With molecular weights ranging from 6 to 30 million and customizable ionic properties (anionic, cationic, nonionic), these polymers adapt to diverse contaminants—from heavy metals in mining effluents to organic matter in textile wastewater. Their rapid dissolution (<90 minutes) and low dosage requirements (0.1–0.3% concentration) make them a cost-effective choice for industries prioritizing sustainability.

Technical Superiority

1.Precision Flocculation PAM’s linear polymer chains neutralize charged particles via electrostatic interactions, achieving >90% turbidity reduction in coal-washing wastewater and 50% COD reduction in dyeing effluents. Cationic variants (CPAM) excel in sludge dewatering, reducing mud cake moisture to <80%, while anionic types (APAM) stabilize drilling fluids in oilfields.

2.Environmental Resilience Formulated to withstand extreme pH (2–12) and temperatures up to 180°C, PAM maintains viscosity retention >80% in harsh conditions, ensuring reliability in thermal power plants and acidic mining runoff treatment.

3.Resource Efficiency Automated dosing systems reduce chemical consumption by 15–20%, and biodegradable formulations minimize ecological impact. Case studies show 40% lower sludge disposal costs in municipal plants.

Cross-Industry Applications

Municipal Wastewater: Addresses seasonal load fluctuations, cutting treatment time by 30%.

Oil & Gas: Enhances oil recovery by 25% through viscosity modification in hydraulic fracturing.

Agriculture: Reduces nitrogen/phosphorus runoff by 60% in CAFOs (Confined Animal Feeding Operations).

Paper Manufacturing: Improves fiber retention by 35%, minimizing raw material loss.

Commitment to Excellence

For tailored polyacrylamide formulations and end-to-end technical support, visit www.polyacrylamidefactory.com. Our ISO 9001-certified production lines deliver customized solutions—whether emulsion, powder, or liquid PAM—backed by 24/7 expertise in water chemistry optimization.